Industry 4.0 at the forefront: more than technology

Industry 4.0, IoT integration, smart factory: keywords that only mean real competitive advantage when paired with a strategic approach. Therefore, we provide not only technology, but also full support and implementation methodology.

What and how do we measure?

We primarily measure complex metrics, such as total asset efficiency (OEE), but we can also extract data from any production machine that directly or indirectly contributes to your company’s performance: throughput, production cycle time, transition time, capacity utilization, schedule or production performance, planned and percentage of emergency maintenance work, productivity, customer rejections / returns, supplier quality.

We provide unified, automated, real-time industrial data collection to help you develop the most efficient production and maintenance strategy for your company with data-driven decisions. Investment-free, cost-effective, without replacing your existing fleet.

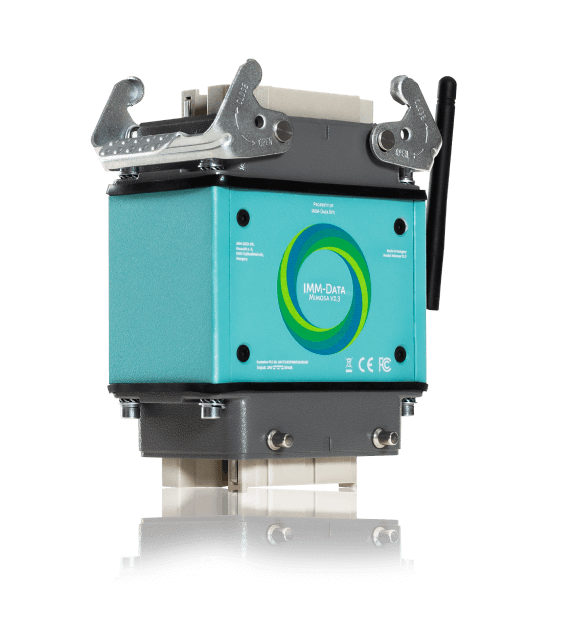

Hardware

The IMM-data hardware solution (Polaris and Mimosa) is a universal data acquisition and transmission device that uses a sensor to find common ground with any production machine that speaks any programming language.

It is easy to use, works on the principle of Plug & Play, it can be completely tailored to the individual needs of your machinery.

Quick start-up

Easy and simple to use, quick installation tailored to your business needs.

Unified data collection

No matter how old your machine is, we can extract valuable data quickly and accurately.

Scalability

Thanks to its modular design, our solution can be flexibly expanded.

Decision support

The right information, at the right time: the foundation of smart decisions.

Automatization

Production optimization even without human intervention: the algorithms work 24/7 for the company.

System integration

It integrates easily with your existing ERP and MES system.

Software

The IMM-data software solution (Saggitarius) is a cloud-based system for data collection, storage and analysis. Its biggest advantage is the real-time analytics interface, where it gives instant notification to the right person when there is a need for intervention.

Some of these processes are fully automated, so production optimization is automatic for certain tasks without human intervention.

Consulting

The introduction of a new technology is not only a technical but also a strategic task, which has a positive impact on the entire operation of the company. Therefore, before, during and after the implementation of the industrial data collection system, you can count on our expertise: we will get the most out of your production.

Expertise

In several industries, in several countries, we have helped many customers to catch up.

Knowledge base

The knowledge we can share is the valuable knowledge. Therefore, we provide a complete educational schedule.

Partnership

We provide a comprehensive implementation methodology tailored to your business needs.

We are proud to see the people behind the numbers: we know there are no template solutions, so we see all our customers as partners.

Our clients