We turn your production data into profit

Get the most out of your production with our industrial data acquisition and analysis system. Production optimization easily, without investment costs.

Play Video

Play Video

Get the most out of production

What you can measure you can improve, too. What you can measure in real time, quickly and accurately, that can give you a significant competitive advantage.

It is worth talking about

ROI calculator

What would your company be able to do with the IMM-Data solution?

What is the actual potential in your company?

Switch to a higher speed with your company, without replacing any machinery.

With our industrial data collection and analysis system, you can reach new heights without considerable investment.

Increasing profits

More efficient production processes and daily work, noticeable changes, even after 3 months.

Cost reduction

Not only the machinery's, but also financial indicators will tell about the enhanced performance.

Competitive edge

The technology is already paying off in the short term, but it has a really significant competitive advantage in the long run.

Transforming data into profit boosting information

It is not enough to measure the data. You need more to increase your profits:

The value

of data

much as how we treat it

Valuable

data

Accurate, unified

automated data collection

Valuable

information

Clear data analysis

and visualization

Profit-raising

information

Real time

decision support

Competitive edge

for your company

Digital transformation

levelling up stress free

Transforming data into profit boosting information

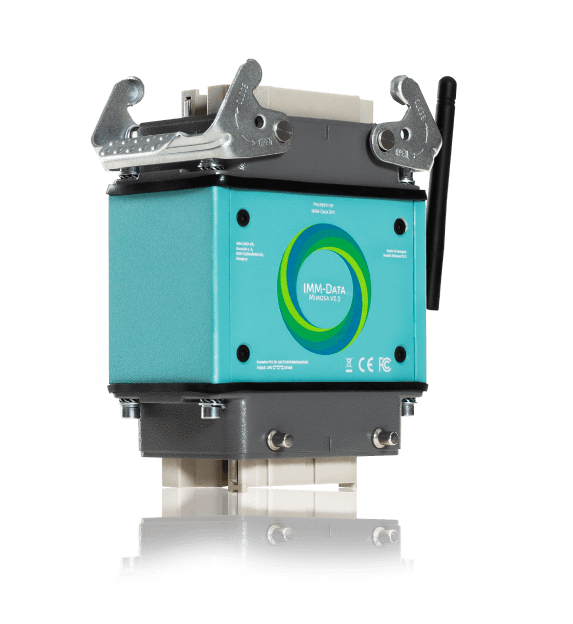

We can extract data from any machine

We create value from all kinds of machine data

You can count on our expertise in everything

Everything is given to level up

Competitive advantage in the SME sector

IMM-data’s industrial data collection system has been fine-tuned specifically for manufacturing companies in the SME sector to remain competitive in the world of Industry 4.0.

Cost reduction

Significant reduction in scrap rates and downtime

Flexible workforce

More transparent, more efficient everyday work

Decision support

More efficient production and maintenance strategy

Production optimization

Increase overall asset efficiency ratio

Automatization

Accurate, fast, real-time data collection and analysis

Digital transformation

Cutting-edge technology and implementation methodology

We collect data, we create value

Real-time data collection is not just about improving the productivity and profitability of manufacturing companies. Our goal is to lay the foundations for the long-term competitiveness of the SME sector, and to provide opportunities for technological advancement.

project

of development

implement

the investment

How do we measure success?

The numbers speak for themselves, but we are the proudest of that we always see the man behind the numbers. That is why we were able to achieve results for our clients, regardless of the industry and the characteristics of the challenges. That is why we are seen as a partner.

Industry experience

The data collection system of IMM-data is an easy-to-use, industry-independent solution for any manufacturing company. At the same time, we have come a long way in the field: our success has been based on our industry experience.

Metal industry

We provide solutions to the data collection challenges of the metalworking industry.

Plastics industry

We have the largest industry experience in the plastics industry.

Food industry

We are currently actively looking for our first test partners who would like to try our solution. Applications are most welcome, under the 'Contact' menu!

Our clients

We are proud to see the people behind the numbers: we know there are no template solutions, so we see all our customers as partners.

Frequently Asked Questions

We will answer everything. Get to know the details!

The essence of industrial data collection is to provide our customers with the data that will be the basis for their manufacturing decisions.

Based on these decisions, our customers can achieve significant cost savings and increased production efficiency.

MM-Data currently offers its solutions for the plastic injection molding and metal processing industries.

Our solution guarantees a return within 6 months and a more efficient, profitable production.

Our customers achieved an average 3-5% scrap rate improvement (along with a better OEE rate) within 12 months.

By evaluating and analyzing the data together, we propose changes in manufacturing technology, that will help us achieve better metrics.

Our customers can view the data on any PC, tablet, laptop or mobile phone.

Data security is paramount to us, so our systems are strictly closed. Data can only be seen by the authorized team / user, within the scope of our Clients.

The essence of industrial data collection is to provide our customers with the data that will be the basis for their manufacturing decisions.

With these decisions, our customers can achieve significant cost savings, as well as increased efficiency and profits.